Wheel alignment sometimes referred to as breaking, or tracking is part of standard automobile maintenance that consists of adjusting the angles of wheels to the car manufacturer specifications. The purpose of these adjustments is to reduce tire wear and to ensure that vehicle travel is straight and true (without "pulling" to one side). Alignment angles can also be altered beyond the maker's specifications to obtain a specific handling characteristic. Motorsport and off-road applications may call for angles to be adjusted well beyond normal, for a variety of reasons.

WE HAVE TWO SERVICE SHOPS IN ERNAKULAM. IN EACH SHOP, WE HAVE TWO ALIGNMENT MACHINES. THEY ARE OF HUNTER, JOHN BEAN & HOFFMAN. THESE MACHINES ARE OF THE LATEST VERSION AND ARE REGULARLY UPDATED. THIS IN TURN HELPS TO GET THE BEST AND ACCURATE RESULT IN OUR SERVICE.

Wheel balancing is the process of balancing the weight of a tire and wheel assembly so that it travels evenly at high speeds. Balancing requires putting a mounted wheel and tire on a balancer, which centers the wheel and spins it to determine where the weights should go. Every time a wheel is first mounted onto a vehicle with a new tire, it has to be balanced. The goal is to make sure the weight is evenly distributed throughout each of the wheels and tires on a vehicle. This process evens out heavy and light spots in a wheel, so that it rotates smoothly. If there is even a slight difference in weight in the wheels, it will cause enough momentum to create a vibration in the car.

In fact, wheels and tires are never exactly the same weight all around. The wheel's valve stem hole will usually subtract a small amount of weight from that side of the wheel. Tires will also have slight weight imbalances, whether from a joining point of the cap plies or a slight deviation from perfectly round. At high speeds, even a tiny imbalance in weight can become a large imbalance in outward force, which could cause the wheel and tire assembly to spin in a heavy and uneven motion. This usually turns into a vibration in the car as well that could cause uneven and damaging wear on the tires.

Maintaining proper wheel balance is a critical part of maintaining the life of the tire. Also proper wheel balancing ensures your vehicle has a smooth and vibration free ride.

WE HAVE TWO BALANCING MACHINES IN EACH SHOP. THE MACHINES USED ARE OF HUNTER & JOHN BEAN. THESE MACHINES ARE ALSO UPDATED AND SERVICED REGULARLY TO GET THE BEST OUT PUT.

A tire changer is a machine used to help tire technicians dismount and mount tires with automobile wheels. After the wheel and tire assembly are removed from the automobile, the tire changer has all the components necessary to remove and replace the tire from the wheel. Different tire changers allow technicians to replace tires on automobiles, motorcycles and heavy-duty trucks. New tire and wheel technology has improved certain tire changers to be able to change a low profile tire or a run-flat tire.

THESE ARE SPECIAL MACHINES WE USED TO MOUNT & DEMOUNT RUN FLAT TYRES AND TYRES OF LOW PROFILE USED IN HI – END VEHICLES.

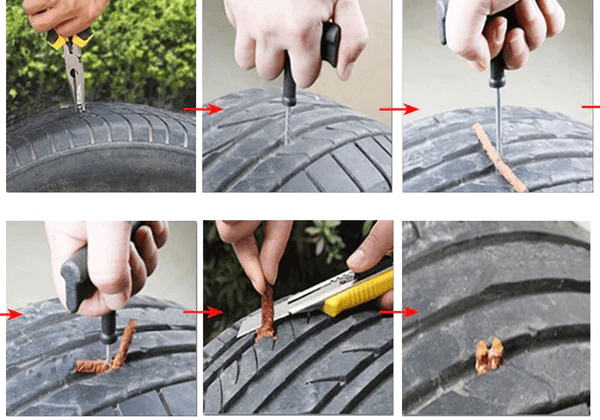

Almost all modern day cars now come fitted with tubeless tyres. As the name suggests, these tyres do not have an inner tube and are mounted on the rim or alloy wheel of the car directly. These are as safe and reliable as a tube type tyre but have a major advantage in the form of air not leaking out immediately in the event of a puncture. But what will you do if you encounter a tubeless tyre puncture?

Repairing a tubeless tyre is a quicker process and can be done by the owner himself. Don’t believe us? Well, read on to know how you can repair a tubeless tyre puncture yourself at home.

The correct way to balance a wheel is, of course, on a dedicated wheel-balance stand. But you can even do a rough job on your bike—the principles remain the same.

For the front wheel, you'll want to loosen the axle pinch bolts and axle to reduce binding, but leave the axle in place.

Remove the brake caliper or push the pads back in the caliper body. For the rear, remove the chain and take off the caliper or push the pads out of contact with the disc.

Slowly spin the wheel and note where it comes to rest. With a piece of tape, chalk, marker, or crayon, mark the 12 o'clock position on the wheel (the light spot).

Turn the wheel 90 degrees to both the 3 o'clock and 9 o'clock positions and see if the light spot returns to the 12 o'clock position on its own. If so, tape a wheel weight onto the rim at the light spot.

Repeat the above step until you've added or removed enough weight that the wheel remains motionless when the light spot is turned to both the 3 o'clock and 9 o'clock positions.

Spoked wheels use crimp-on fishing-sinker-type weights, while cast wheels use adhesive-backed lead weights. An old-school substitute for spoked wheels is a string of lead solder wrapped around the spoke and crimped on with a pair of pliers.

Nitrogen is chemically a non-flammable, non-toxic inert gas. An inert gas does not fuse with any other gas at any temperature. This basic nature of nitrogen first of all helps in keeping minimum moisture in the tyres. The basic idea of Nitrogen gas is that it is cooler than compressed air and therefore is useful in any driving conditions. Why? A cooler tyre means that the stress levels on the tyre while moving are lesser. The tread wear and tear is also lesser due to the lesser temperature.

Higher temperature in tyres also has a tendency to burst after long hours of running. Nitrogen reduces the chances of tyre burst by 90%. This can prove to be a lifesaver while on the highway where long hours and high speed, both pose a threat to the car and its passengers.

Copyright © 2022 Speed Tyres. All Rights Reserved. Web Design Company In Kochi - Techsoft